How about some numbers? – Why data quality requires specialists

Experienced captains, officers and engineers know how important quality work is. And this of course applies to data as well. Running a superyacht is not an easy job and requires skill and dedication. But to smoothly operate such a high-value asset and provide the ultimate experience for owners and guests requires more. A structured way of working is essential. And that means knowing exactly what needs to be done regarding safety, maintenance, inventory and much more. Crew need to know which task needs to be done when, how to perform the task and what all is required to do the job properly. That’s exactly the reason why systems like IDEA YACHT exist and are so crucial to the successful operation of any superyacht.

However, the best systems are useless without solid and reliable data. Because as we all know, bullshit in means bullshits out. And that is why IDEA doesn’t stop by providing ‘just’ software. Because we know from the experience of more than 1100 projects over the last 20 years how important the quality of data is. Having built over 450 databases for superyachts ranging from less than 30m up to 120m(+), we would like to share some insights about the work of IDEA’s professional service team. And what it takes to build a top-quality vessel database and planned maintenance system (PMS).

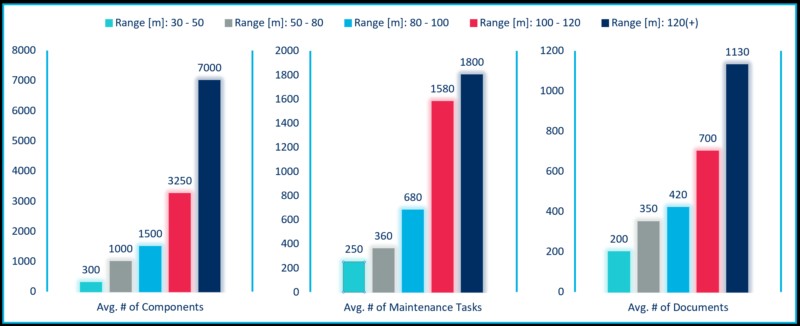

Converting shipyard, supplier and manufacturer information into an operational setup and collecting, filtering, and structuring all relevant data is a massive task. Especially when dealing with larger vessels. Every captain, officer and chief/build engineer knows how busy the period shortly before delivery of a vessel is. And that’s typically the time when the ‘real’ as-built data becomes available. Looking at the figures the average number of relevant equipment requiring maintenance on a 30m – 50m vessel ranges from 200 to 400. Whereas this number rapidly increases with the size of the yacht. Looking at an 80m – 100m superyacht the number of components already ranges between 1.000 and 2.000. And looking at even bigger super- or mega yachts up to 120m and more the number increases to a stunning 4.000 to 10.000 components.

Similarly, the related numbers of maintenance tasks and documents grow with the increasing amount of equipment installed on a yacht. Again, taking the 30m – 50m range the number of required maintenance tasks is 250 on average. Whereas this grows constantly to 1.800 on average looking at a 120m(+) vessel. And of course, the same holds for the average number of documents, including drawings, schematics, diagrams, and manuals. Starting at around 200 documents on average for a 30m – 50m long yacht, up to almost 6 times as much (over 1.100 documents on average) for a 120m(+)yacht.

Looking at these numbers is already impressive. However, this is just the starting point to build a top-quality vessel database and PMS. Because all these components need to be checked and translated into an operational logical structured database. On top of that comes that all equipment needs to be located and photographed. Besides the fact that all required documents need to be linked. To finally be able to program the planned maintenance part of the system, this does not even include the enormous number of spare parts which are required and need to be included in the system.

So, in conclusion, one can say that it requires countless hours of work, special knowledge and experience to build a comprehensive database and PMS that is as-built, accurate and well structured, hence of real top-quality.